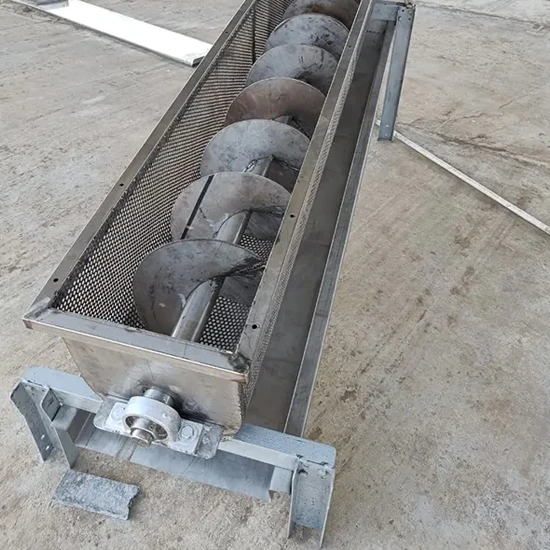

Conveyer Dry Machine

Conveyor Dry Machine – Continuous Drying for Enhanced Production Efficiency

5-stage continuous conveying dryer is a versatile piece of equipment used for drying various produce such as onions, garlic, turmeric, ginger, carrots, cabbage, chillies and other vegetable products on a continuous basis. Here’s an overview of its structure and operation:

Structure and Components:

1. Five Belts : The dryer has five belts arranged vertically. Each belt has its own drive mechanism, allowing them to move independently.

2. Heating Coils : These are provided to ensure precise control of the drying temperature.

3. Hot Air Flow : The hot air passes through the permeable bed of material on each belt, which aids in effective drying.

4. Fans: Located at the top of the dryer, fans are used to exhaust moist air from the system.

Operation :

Feeding : Fresh material is fed onto the top belt.

Material Transfer : As the material reaches the end of each belt, it is transferred to the belt underneath. This continues until the material

reaches the bottom belt.

Drying Process : The air, heated to the desired temperature, rises from the bottom and passes through each belt, drying the material as it moves downward.

Exhaust : Moist air is expelled from the dryer by the fans at the top, ensuring that the drying process is efficient.

Advantages:

Continuous Operation : The system allows for continuous feeding and drying of materials, which is efcient for large-scale operations.

Effective Drying : The design ensures that hot air passes through the material bed uniformly, providing consistent drying results.

Conveyer Dry Machine

Conveyor Dry Machine – Continuous Drying for Enhanced Production Efficiency

5-stage continuous conveying dryer is a versatile piece of equipment used for drying various produce such as onions, garlic, turmeric, ginger, carrots, cabbage, chillies and other vegetable products on a continuous basis. Here’s an overview of its structure and operation:

Structure and Components:

1. Five Belts : The dryer has five belts arranged vertically. Each belt has its own drive mechanism, allowing them to move independently.

2. Heating Coils : These are provided to ensure precise control of the drying temperature.

3. Hot Air Flow : The hot air passes through the permeable bed of material on each belt, which aids in effective drying.

4. Fans: Located at the top of the dryer, fans are used to exhaust moist air from the system.

Operation :

Feeding : Fresh material is fed onto the top belt.

Material Transfer : As the material reaches the end of each belt, it is transferred to the belt underneath. This continues until the material

reaches the bottom belt.

Drying Process : The air, heated to the desired temperature, rises from the bottom and passes through each belt, drying the material as it moves downward.

Exhaust : Moist air is expelled from the dryer by the fans at the top, ensuring that the drying process is efficient.

Advantages:

Continuous Operation : The system allows for continuous feeding and drying of materials, which is efcient for large-scale operations.

Effective Drying : The design ensures that hot air passes through the material bed uniformly, providing consistent drying results.

Product Specification

Optimize Your Dehydration Process with Durable Conveyor Belts(Size: 30 Ft / 8 Ft / 2 Stages)

Output Capacity : 276 Kg / hr (Finished material)

Standard Blower CFM 6500 Pressure 80 Mm

Material Contact Parts : S.s. 304 & Other Suitable Material

Motor : 5hp/2, 1hp/1, Blower 5hp/2

Material Coverer Belt : 304 #9 Mesh

Gar Box : B 90

Air Chamber pipe : 100 mm GI Material

Supporting Roll pipe : 40 mm GI Material

Radiator Pipe : 30 mm MS Material

Radiator Box : GI Material

Drum Roll Pipe : 270 mm MS Material

Barring Size

208 UCP 40 mm Qty. 4

208 UCT 40 mm Qty. 4

204 UCP 19 mm Qty.4

TOTAL HP LOAD 11 hp